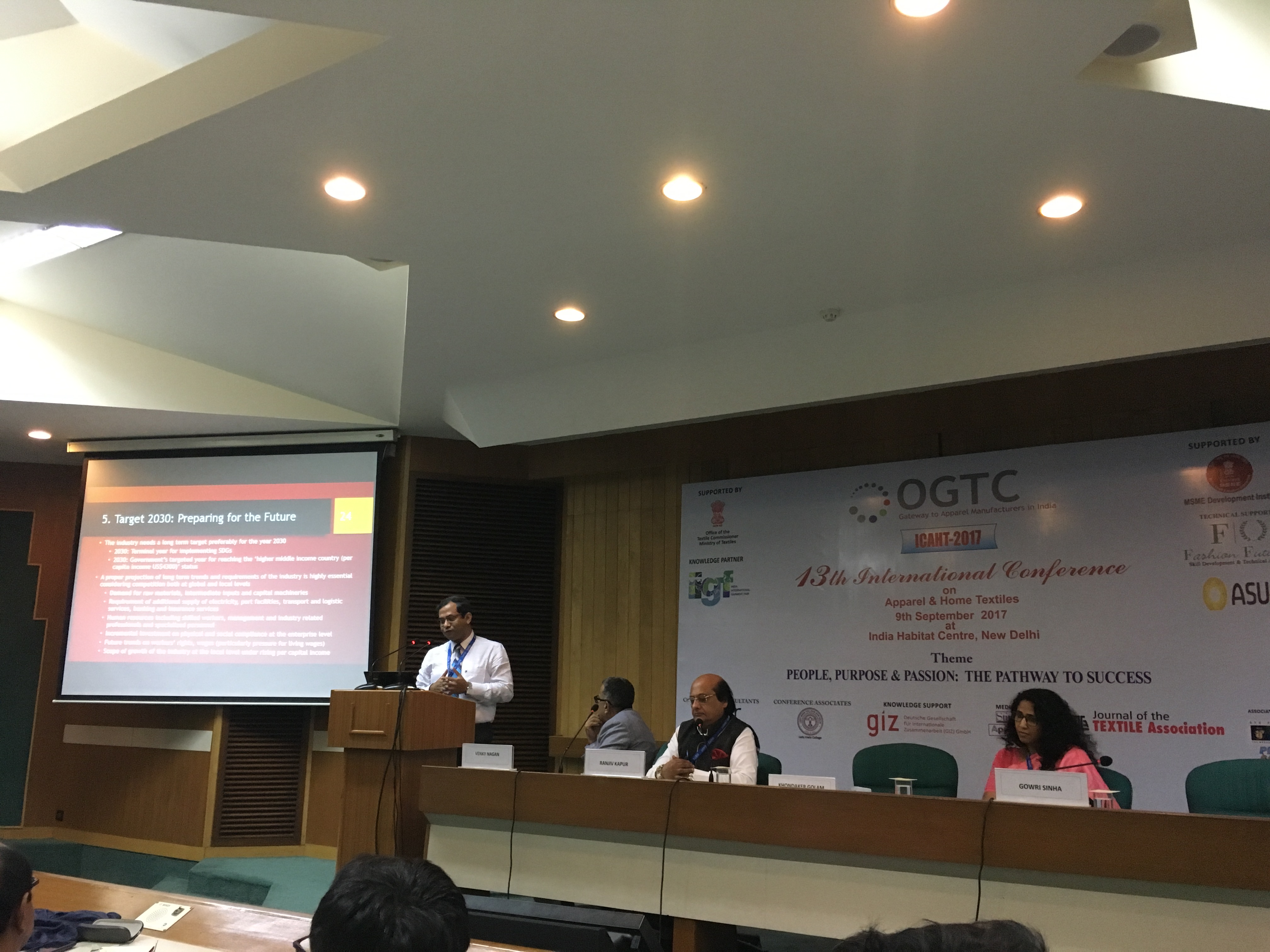

Center for Policy Dialogue Research Director Dr Khondaker Golam Moazzem presented a paper at the 13th International Conference on Apparel & Home Textiles held on September 9, 2017 at India Habitat Centre, New Delhi.

OGTC has been organizing International Conferences on Apparel & Home Textile every year since 2005. The year the theme of the Conference was “People, Purpose & Passion: The Pathway To Success.

In his presentation, Dr Khondaker Golam Moazzem said that Bangladesh’s RMG factories needs to take preparation to address challenges of the coming years.

“First, Bangladesh’s RMG industry needs to enhance its productivity with a view to address the erosion of trade preferenceswhen it will graduate from the LDC category possibly by 2024. Second, Bangladesh may confront challenges in case of bilateral trade with Britain as well as with the EU when the negotiation of Brexit will be over in 2019. Third, Bangladesh is increasingly facing the competition from a number of its competing countries such as India and Vietnam for possible loss of preferential margin after these countries will sign bilateral free trade agreements with a number of developed countries/markets such as EU and Britain also which are major export destinations for Bangladesh’s apparels,” the paper reads.

Here is the full document :

“Bangladesh Road Map for Apparel Industry”

Dr KhondakerGolamMoazzem

Research Director

Centre for Policy Dialogue (CPD), Bangladesh

The road map for Bangladesh’s export-oriented apparels sector was never explicit in the public domain.Instead the roadmap was ‘implicit’ in public policies and responses of the private sector in those policies. For the first time the business associations related to the apparels sector mainly Bangladesh Garments’ Manufacturers and Exporters Association (BGMEA) and Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA) has unveiled their long term target of export of apparels in December, 2014 i.e. ‘Achieving US$50 billion worth of apparels export by 2021 when Bangladesh will enjoy its 50th Anniversary of Independence.’More importantly, this export target has been accommodated in successive development policies especially in the 7th Five Year Plan which will be implemented in 2016-2020. Since the export target was set assuming an export growth over 12 per cent, immediately after the announcement the private sector realized the difficulty in achieving such high rate of growth in successive years (strikingly, during last fiscal year (July, 2016 to June, 2017) export growth was only 0.2 per cent on year-on-year basis). This sluggish growth is likely to continue because of pressure on export both through ‘volume effect’ and ‘price effect’ mainly due to sluggish demand for apparels in the global market. Moreover, the roadmap related documents did not elaborate how to achieve long term targets by addressing strategic issues including products, processes, technologies, markets, human resources and foreign investments etc. Hence, the ‘functional’ roadmap of the RMG industry is rather a combination of acts and initiatives of government at the macro level and approached and initiatives undertaken by the private sector at the micro level taking support of major market players including the buyers/brands.

Bangladesh’s apparel industry has been undergoing a transitional period since the tragic incidences of collapse of the Rana Plaza in 2013 and fire incidence of Tazreen Fashions garments in 2012. The sector has experienced massive restructuring and reform particularly focusing on social and physical compliances including workplace safety and security in RMG factories. As part of this, the labour law has been amended in 2013 and is likely to be amended further, new guidelines of subcontracting activities has been drafted, buyers/retailers/brands have changed their sourcing strategies. The entrepreneurs particularly those who have small and medium sized enterprises and those who operate under subcontracting arrangements have been facing number of challenges including shortages of capital for remediation related activities andlack of export orders for factories located in shared buildings, relatively slow growth in export orders as well as low rates for cutting and making charges. Moreover, there is pressure for further rise in workers’ wages as the last revision of wages took place about four years back. Moreover, weak infrastructure particularly in terms of supply of gas, electricity, poor road and rail connectivity and slow turn-around in sea ports raise risks and consequently cost of doing business and more importantly, discourages buyers to place increased volume of export orders. Hence the prospect of apparels export at least in short term and partly in medium term is not so bright.

However, public investment over the last decade has put special emphasis in building trade-based infrastructures in the country. As a result, a number of important roads and rail connectivity have improved and a number of other infrastructure related projects are at different stages of implementation including establishment of special economic zones (SEZs), setting up liquefied natural gas (LNG) plants for smooth supply of gas, andconstruction of Padma Multipurpose Bridge over the river Padma to ensure smooth connectivity with the Southern part of Bangladeshetc.With successful implementation of these projects, the ‘infrastructure deficit’ of the country is likely to met to some extent.

Bangladesh’s RMG industry needs to take preparation to address a number of challenges of the coming years. First, Bangladesh’s RMG industry needs to enhance its productivity with a view to address the erosion of trade preferenceswhen it will graduate from the LDC category possibly by 2024. Second, Bangladesh may confront challenges in case of bilateral trade with Britain as well as with the EU when the negotiation of Brexit will be over in 2019. Third, Bangladesh is increasingly facing the competition from a number of its competing countries such as India and Vietnam for possible loss of preferential margin after these countries will sign bilateral free trade agreements with a number of developed countries/markets such as EU and Britain also which are major export destinations for Bangladesh’s apparels. Fourth, Bangladesh may confront strong competition from a number of new and emerging apparels exporting countries. Besides, the entrepreneurs need to address a number of dynamic issues in the coming years including changes in technologies,economic and social upgrading in the value chains,inter-generational issues with regard to entrepreneurship, corporate management, investment including FDI, market diversificationretail businesses, spatial shifting of import orders and sharing more responsibilities between buyers and suppliers.

The success of the apparels sector in the future will largely hinge on higher level of productivity, better quality of products and better working environment and ensuring labour rights. In this context, a proper blend of economic and social upgrading in the production segment of the value chain is one of the important prerequisites. In the long run, the sector needs to take a ‘high path road’ including technologies, upgrading the product base,strengthening the mid-level management, transfer of ownership to the next generation, allowing foreign direct investment (FDI) in specialized products as well as in backward linkage part of the value chains, exploring export opportunities in non-traditional markets and opportunities for outward investment of local entrepreneurs etc. Besides, the sector needs to be more flexible and responsive towards occupational safety and health (OSH), labour rights and other types of support including accidental insurance and welfare benefits, facilities for housing and better nutritional facilities and environmental compliance issues. The ongoing initiatives of safety related measures need to be institutionalisaed by strengthening the public authorities including Department of Inspection of Factory Establishment (DIFE) by setting up Remediation and Coordination Cell (RCC) and Department of Labour (DoL) and Fire Service and Civil Defense Authority (FSCD). The buyers and brands need to take shared responsibilities in terms of ensuring decent wages and employment in the RMG value chain. The development partners should continue providing their support with regard to accessing technical and financial support in terms of improvement in social and labour compliance as well as environmental compliances.

CPD RMG Study Stitching a better future for Bangladesh

CPD RMG Study Stitching a better future for Bangladesh