Published in Forbes on March 30, 2018

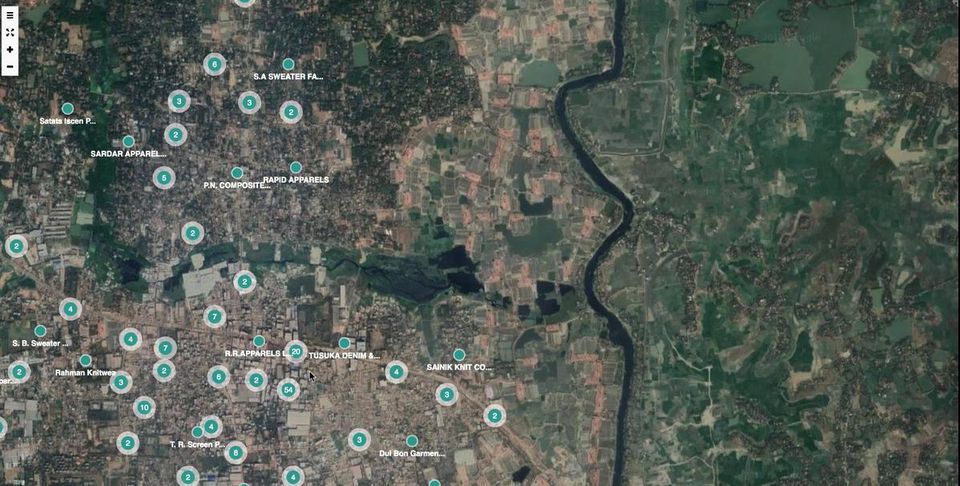

Sourcemap, a New York City tech start-up is building a platform, that could transform the fashion industry: a digital map of all clothing manufacturers in Bangladesh.

Bangladesh has long been at the heart of textile manufacturing (estimated at $28 billion just behind China); yet it’s also struggled with factories that fail to treat workers fairly and in horrific working conditions, which have led to disasters such as Rana Plaza nearly 5 years ago.

Sourcemap uses a supply chain mapping and transparency platform, developed at MIT, to help large global companies have greater transparency and accountability of their entire supply chain. With the help of a grant by C&A Foundation, the company hopes to map out each textile factory in the country, beginning within Dhaka, and provide details of their certifications, compliance reports, and manufacturing practices.

“Right now, nobody has an idea of how many factories, where they’re located, what do they produce, what do they do, how many people work there… no one has a full picture,” says Parveen Sultana Huda of BRAC who is managing this digital project from Dhaka. “This sector brings us a lot of foreign currency. So this is the sector to invest in.”

Sourcemap is partnering with BRAC University (BRACU) in Bangladesh to administer the survey. BRAC, one of the largest non-profits in the world, has focused on improving the quality of life for Bangladeshi through livelihoods, not charity.

Bangladeshi data collectors will use mobiles to aggregate thousands of GPS-linked data points collected on the ground from factory owners, workers and organizations.

“The Sourcemap team is committed to working closely with local partners in Bangladesh to design the right interface from start to finish, “ says Rhea Rakshit, head of design for Sourcemap. “The goal is to make it as simple as possible to collect data from factories on the ground, and then allow apparel brands and other stakeholders to gain access to it through an easy to use mapping platform.”

Data from 12-point census will detail conditions as reported by Bangladeshi factories, unions, and workers. In addition to factory and worker statistics, licensure and safety data, the names of clothing brands that each factory manufactures will also be captured and published. That data will then be uploaded to a public digital map, designed and maintained by Sourcemap on cloud servers.

The crowdsourced supply chain map is the first of its kind for the global apparel industry, Sourcemap says.

The map will be open to all brands and buyers free of cost, in the hopes that international buyers can then easily track a supplier, without having to comb through the riff-raff. It will also encourage factories to become more compliant, if not already, in an effort to attract more business. Sourcemap says that government agencies are keen to use the database to inspect and monitor the apparel sector as well.

C&A Foundation is funding the project through BRAC USA for 1.75 million Euros over four years. While not a traditional finance investment, this could become a model for other supply chains. For instance, C&A Foundation is also funding a similar project with Sourcemap to build a platform and tool for apparel factories worldwide, or the Open Apparel Registry (OAR). Think Google Maps for factories.

In the meantime, this project will hopefully bolster the “Made in Bangladesh,” which has long been tarnished by disasters in the textile industry.

“We don’t want to close any of these factories,” says Huda. “What we want is a collective approach to improve working conditions for everyone who is working directly or indirectly in this sector.”

CPD RMG Study Stitching a better future for Bangladesh

CPD RMG Study Stitching a better future for Bangladesh